Ball Mill Success: A Comprehensive Guide to Selecting the Appropriate Grinding Media 8 August, 2024 grinding-milling

Overview

In the complex process of ball milling, which involves the transformation of raw materials into finely milled particles, the selection of grinding media plays a crucial role in determining performance outcomes. The seemingly insignificant choice of this particular pick can have a profound impact on the effectiveness of the milling procedure, the calibre of the end product, and, eventually, the financial outcome. The appropriate selection of grinding media can result in significant improvements in efficiency and product quality, whether in the fields of medicines, ceramics, or materials science.

This article provides a detailed guide that will help you choose the most appropriate grinding media for your individual milling requirements. Our primary objective is to improve the efficiency of your milling operations and the overall quality of your end product.

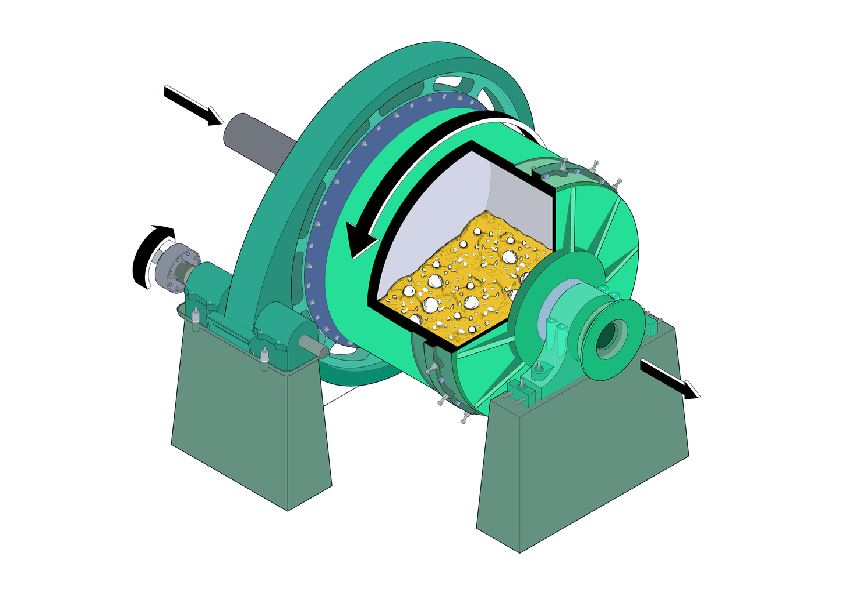

An Explanation of Ball Milling

Ball milling is a mechanical procedure employed to pulverise and mix materials in order to produce smaller particles. During this procedure, a combination of powders is introduced into a revolving cylinder, together with grinding medium like balls. The balls' velocity imparts kinetic energy that fractures the powder into smaller fragments, rendering it a crucial technology in several industries. In the field of mining, it is employed for the purpose of ore processing, facilitating the retrieval of valuable minerals. The pharmaceutical sector depends on it to provide consistent particle sizes, hence improving the solubility and absorption of drugs. Ball milling is advantageous for ceramics as it enables the production of finely ground and uniform powders, which are crucial for the creation of superior pottery and tiles.

The subject of the text is the Wikipedia page on ball mills.

Rusch, Heather, the originator, Public domain, through Wikimedia Commons

The selection of grinding medium is a critical factor in influencing the effectiveness of the ball milling procedure. The energy transfer during milling can be considerably influenced by the various materials, sizes, and densities of grinding media, which in turn affects the rate and uniformity of particle size reduction. Therefore, this decision has a direct impact on the quality of the product, specifically affecting attributes like as purity, particle size distribution, and surface area. Furthermore, the choice of grinding media can result in fluctuations in operational expenses, as aspects like media longevity, energy usage, and maintenance requirements all contribute to the overall cost-efficiency of the milling process. Therefore, comprehending the interaction between grinding medium and milling results is crucial for optimising both the procedure and the final product.

Learn more: Grinding and Milling: The Two Fundamental Machining Techniques

Grinding media can be classified into many types.

Grinding media, which are crucial for the effectiveness of the ball milling process, are available in different materials, each with distinct characteristics and advantages that are customised for specific purposes.

Ceramic balls, made from substances such as silicon nitride, alumina, and zirconia, are highly valued for their remarkable hardness and ability to withstand wear, corrosion, and high temperatures. These characteristics make them well-suited for applications that demand high levels of purity and little contamination, such as in the pharmaceutical, food processing, and advanced ceramics production industries. Ceramic balls preserve the integrity of the milled product by preventing any degradation of the material and any chemical interaction. Their low weight also helps to decrease energy usage during milling.

Steel balls: Steel balls, primarily composed of carbon steel, stainless steel, or alloy steel, are well-known for their exceptional density and impressive impact resistance. These characteristics make them particularly well-suited for demanding milling operations in the mining and cement industries, where durable grinding media are necessary to effectively crush tough materials. Steel balls are highly prized for their exceptional durability and cost-efficiency, providing a harmonious combination of initial expenses and long-term operational lifespan. Nevertheless, they can potentially cause contamination in delicate products, which restricts their employment in specific medicinal and food contexts.

Further information can be found in the article titled "Ceramic vs. Steel Grinding Balls: A Comprehensive Comparison for Industrial Use".

Additional materials, such as glass and plastic balls, have specific uses in certain situations where their chemical inertness and specific gravity are important factors. Glass balls are employed in milling conditions that are non-abrasive, usually in situations where it is crucial to prevent any form of contamination. Plastic balls, which have the lowest density compared to other grinding media, are used in situations where minimum impact strength is needed and chemical compatibility is extremely important.

The file is named "Ball mill.gif".

Lưu Ly, an image in the public domain, available via Wikimedia Commons

Choosing the appropriate grinding media requires thoughtful evaluation of the material to be milled, the desired properties of the finished product, and the specific process demands, in order to achieve the best possible milling effectiveness and product excellence.

Key Considerations for Selecting Grinding Media

Choosing the appropriate grinding medium is a crucial factor in the ball milling process, as it impacts both the efficiency of the operation and the overall quality of the end result. To achieve the best results and cost efficiency in the milling process, it is important to take into account several crucial elements.

Material Composition: The precise chemical makeup of the grinding medium is of utmost importance, as it directly affects the purity of the result and the possibility of chemical reactions occurring during the milling process. For example, ceramic balls composed of elements such as alumina or zirconia are chemically inactive, making them appropriate for situations where the presence of impurities could jeopardise the quality of a product, such as in the pharmaceutical or food manufacturing industries. On the other hand, steel balls may bring about iron contamination, although they are favoured in situations where this does not impact the product, such as specific mineral processing procedures.

Learn more: Material Selection: A Guide to Choosing the Appropriate Grinding Balls and Jars

The size and shape of the grinding media have a considerable impact on the efficiency of the milling operation and the granularity of the finished product. Smaller media have the ability to achieve more precise particle sizes, although this may necessitate longer periods of grinding. On the other hand, bigger media can reduce size more quickly but may not reach the appropriate level of fineness. The morphology of the media also influences the milling process, as spherical balls tend to be the most effective due to their capacity to roll and cascade efficiently.

The wear rate, efficiency, and durability of the grinding media are influenced by their hardness and density. More resilient and compact materials, such as specific ceramics and steels, have the ability to withstand the milling process for a longer duration, resulting in a decrease in the need for media replacement and ensuring a consistent milling environment throughout time. Excessively rigid media might potentially cause harm to the material being processed, emphasising the importance of finding a suitable equilibrium depending on the specific task at hand.

Cost-effectiveness: The initial expenditure on grinding media must be balanced against their operational longevity and maintenance requirements. Although ceramic balls may be initially more expensive, their long-lasting nature and reduced rate of wear might result in greater cost efficiency in the long run, leading to a decrease in overall operational expenses. While steel balls may have a lower initial cost, they may necessitate more frequent replacements, leading to higher long-term expenses.

Factors that have a significant influence on a situation or outcome, together with important factors to take into account.

Material: Ensuring the purity of products and understanding their reactions.Ceramic is chosen for its purity, whereas steel is selected for its endurance.

Dimensions & ConfigurationEfficiency and particle size distribution in millingFor more precise sizes, use smaller particles. To get better efficiency, use spherical particles.

Physical Properties: Hardness and DensityRate of wear and level of durabilitySelect equilibrium to prevent harm.

Cost: Comparing upfront costs to long-term expensesCeramic is preferred for its high value, while steel is chosen for its lower initial cost.

This concise table effectively summarises key factors to consider when choosing grinding media, with a specific emphasis on the most crucial features to assist in the decision-making process.

Thoroughly evaluating these parameters allows for the choice of grinding media that is most suitable for the individual needs of the milling process, guaranteeing effective operation, top-notch products, and economically efficient production.

Comprehensive Selection Guide

Selecting the appropriate grinding medium for ball milling requires a careful evaluation to ensure compatibility with operational objectives, material properties, and financial limitations. Here is a systematic way to help streamline this crucial decision-making process:

Step 1. Evaluating Milling Needs:

Prior to milling, it is essential to conduct a comprehensive study of the material. Take into account its level of hardness, abrasiveness, and chemical characteristics. It is essential to explicitly define the desired attributes of the end product, such as particle size, shape, and purity. Furthermore, assess the milling parameters, such as the mill type, velocity, duration, and whether the procedure is conducted in a wet or dry environment. These criteria will impact the choice of the most appropriate grinding media.

Step 2. Media Type Comparison:

Thoroughly analyse the various options for grinding media in relation to the specific milling needs. Ceramic balls possess exceptional durability and exhibit minimal contamination, rendering them highly suitable for applications that demand utmost purity. Steel balls, renowned for their durability, are more suitable for demanding milling operations where the hardness of the material plays a crucial role. Evaluate the advantages and disadvantages of each media type based on your individual requirements. Consider the material composition, size, form, hardness, density, and cost-effectiveness. The comparison should be in accordance with the milling specifications and operational goals established in the initial phase.

Step 3. Experimentation and Evaluation:

Prior to making a final decision, carry out trial experiments with the chosen grinding media. Testing enables the assessment of the media's performance in actual milling conditions, offering valuable information on wear rate, efficiency, and its effect on product quality. Additionally, it provides the chance to modify the milling parameters in order to optimise the operation. Ensuring that the selected grinding media matches the desired results without any unexpected problems or expenses is a critical step.

1. Identify the action to be taken. 2. Determine the key considerations for the action.

1. Materials and ConditionsEvaluate the characteristics of the material (such as hardness, abrasiveness, and wet/dry conditions) and the parameters of the milling process.

2 Comparing MediaAnalyse the composition, size, hardness, and cost of ceramic and steel media.

3 Testing Experimentation conducted to assess the effectiveness of media and make necessary adjustments for optimal performance.

This concise table effectively summarises the necessary procedures and factors to consider when choosing grinding media, making the decision-making process more straightforward.

By adhering to this advice, you may make a knowledgeable choice of grinding media, guaranteeing that it not only fulfils the particular demands of your milling procedure but also adds to the overall triumph and cost-effectiveness of your operations.

Illustrative Analyses and Instances

The adoption of ceramic grinding balls in the pharmaceutical sector resulted in a notable enhancement in the purity and quality of active pharmaceutical ingredients (APIs). An exemplary instance entailed a company grappling with contamination problems with steel balls, which had an adverse impact on the uniformity and efficacy of their treatment. Through the adoption of zirconia balls, they saw a significant enhancement in the purity of the product, without any detectable presence of impurities. This resulted in improved effectiveness of the treatment and increased safety for the patients.

A copper processing plant in the mining industry faced challenges with ineffective ore grinding using conventional steel balls, resulting in suboptimal mineral recovery rates. Upon doing an analysis of their milling circumstances, they made the decision to use high-density steel balls. These balls had the necessary impact strength to effectively break down the copper ore. The observed modification led to a discernible augmentation in the rates of recovery, illustrating the direct influence of appropriate grinding medium on the operational efficacy and profitability of mineral processing processes.

In conclusion

The careful choice of grinding media is essential for optimising the efficiency and efficacy of ball milling processes. The selection of grinding media has a significant impact on the quality of the end product, operational expenses, and overall process effectiveness, as demonstrated by many factors and practical instances. Whether the goal is to increase the purity of pharmaceutical products or to optimise the recovery rates in mineral processing, the consequences of this decision go beyond just cost considerations and have a significant impact on the fundamental results of milling activities.

Reference:

https://www.preciseceramic.com/blog/a-step-by-step-guide-to-choosing-the-right-grinding-media.html