Introduction

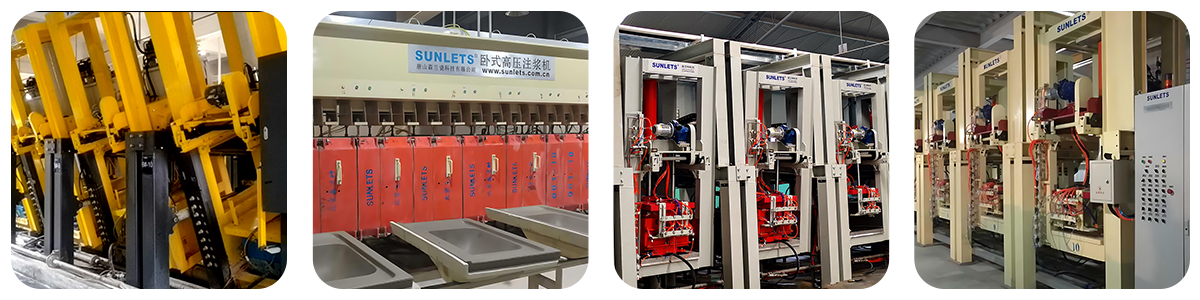

Amidst the global bathroom manufacturing industry's shift towards intelligent and efficient production, innovations in forming processes have become pivotal to corporate competitiveness. While most domestic enterprises still rely on traditional manual plaster mold slip casting, high-pressure slip casting technology—as a core process in modern ceramic manufacturing—has long dominated among leading international brands, supporting 60%-80% of their product lines. This technology forces slurry into precise molds under high pressure, enabling comprehensive coverage of product dimensions and complex shapes—from sinks and countertop basins to toilets. It serves as strategic equipment that liberates labor and reshapes production processes. We will now delve into the advantages and applications of high-pressure slip casting technology.

I. Principles and Core Control Points of High-Pressure Slip Casting

| High-pressure slip casting is a pivotal technology in modern sanitaryware manufacturing, centered on mechanically driving rapid slurry dewatering and dense molding. Unlike traditional plaster molds that rely on natural slurry absorption, this technology applies high pressure to rapidly expel moisture and consolidate particles within sealed molds. This enables the formation of structurally uniform, high-density green bodies within minutes. This breakthrough not only drastically shortens the forming cycle but fundamentally enhances the mechanical properties and dimensional stability of the green bodies. |  |

Key Control Elements in Technical Implementation

Slurry Performance Regulation | Pressure System Optimization | Mold Design and Maintenance | Quality and Porosity Control |

As the foundation of molding, slurry rheology, solids content, and stability directly impact filling efficiency and green body quality. An optimal slurry must balance high fluidity with appropriate viscosity. This requires precise raw material ratios and mixing processes to achieve uniform particle dispersion, preventing porosity or defects caused by localized agglomeration or viscosity control failures. | Slurry injection pressure and holding time are core process variables. Insufficient pressure leads to porous structures and inadequate strength, while excessive pressure or rapid pressurization risks cracking the green body or damaging the mold. A reasonable pressure curve and dwell time must be established based on product geometry and slurry characteristics. | As the critical carrier for pressure application and forming, mold structures must eliminate slurry flow dead zones. Surfaces should exhibit excellent microporous permeability and wear resistance. Optimal mold design not only enhances filling efficiency but also directly impacts green body surface quality and demolding effectiveness. | Porosity serves as a critical indicator of green body quality; excessive porosity compromises mechanical properties and durability. Systematic control requires comprehensive management spanning raw material purity, slurry preparation, injection parameters, and sintering processes. By optimizing inter-process coordination and parameter ratios, harmful voids can be effectively reduced, enhancing overall product consistency. |

The high-pressure slip casting process achieves efficient dehydration and dense forming through mechanical pressure. Its technical advantages depend on the systematic coordination of multiple elements, including slurry composition, pressure application, mold design, and thermal treatment. Only through comprehensive, precision control throughout the entire process can this technology fully realize its potential for enhancing product quality and production efficiency.

II. Advantages of High-Pressure Slip Casting

| Production Efficiency Advantages | Product Quality Advantages | |

| High-pressure slip casting technology significantly boosts production efficiency by optimizing the forming process. Under high pressure, the slurry rapidly fills the mold cavity, reducing single-piece forming time to 3-5 minutes—a 30%-50% increase in output compared to traditional methods. Combined with precise pressure maintenance control (45-90 seconds), it enables rapid demolding and continuous production. Daily output surges, enhancing equipment utilization and productivity. | The high-pressure environment densely packs slurry particles, increasing green body density by 15%-20%. After firing, water absorption is stably controlled at ≤0.5%, significantly extending product lifespan. Combined with vacuum degassing, internal bubbles are effectively eliminated, reducing porosity by over 50%. Particularly suited for products with complex curved surfaces like smart toilets, this process improves surface quality and reduces post-processing requirements. | |

| Cost Control and Labor Savings | Environmental Sustainability and Design Adaptability | |

| High-pressure slip casting increases slurry solids content to 68%-72%, effectively lowering energy consumption during drying. Automated equipment reduces single-line operator requirements by 60% while maintaining scrap rates below 3%, achieving comprehensive cost optimization across raw materials, energy, and labor. | This process enables one-step molding of intricate shapes, precisely replicating fine textures and three-dimensional structures to unlock greater design freedom. Environmentally, the adoption of green auxiliary materials—such as sodium-free demulsifiers and bio-based defoamers—reduces wastewater discharge by 40%. This compliance with international environmental standards supports enterprises in achieving green manufacturing transformation. |

III. Applications of High-Pressure Slip Casting

High-pressure slip-cast ceramics are widely used in manufacturing across electronics, machinery, and chemical industries, including electronic ceramics, mechanical seals, and chemical pipelines. Additionally, this process can produce various ceramic products featuring complex shapes and intricate designs. As a ceramic manufacturing technique characterized by high precision, efficiency, and quality, high-pressure slip casting holds broad application prospects in the ceramic manufacturing sector.