Introduction

In the ceramic manufacturing industry, the efficiency and capacity of the forming process directly determine a company's market responsiveness and production costs. With diversifying market demands, rising energy costs, and shifts in the labor structure, systematically enhancing forming efficiency has become a core challenge for enterprises to maintain competitiveness. Based on over two decades of industry practice, the following key points have been identified:

I. Establishing Automated and Intelligent Production Systems

In raw material batching, fully automated precision weighing systems reduce traditional manual batching time to one-sixth of the original while significantly minimizing human error. During body preparation, vacuum extrusion technology effectively removes air bubbles from the clay, markedly improving body density and uniformity. This reduces deformation and cracking risks during subsequent sintering. As the most energy-intensive stage, sintering's control precision directly impacts both production capacity and quality. Modern intelligent kiln control systems enable real-time adjustment of temperature curves and oxygen levels. This shortens firing cycles, reduces product energy consumption, and minimizes unplanned downtime through early warning mechanisms, thereby safeguarding production output.

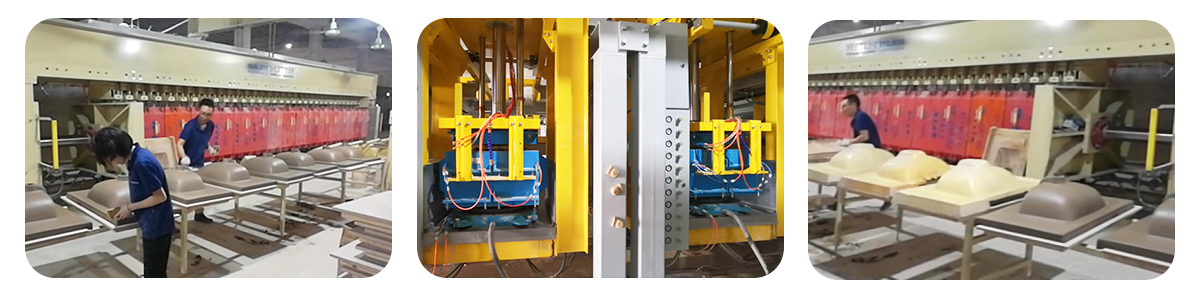

II. Forming Process and Mold Design Optimization

Forming process optimization focuses on “precise control” and “smooth forming.” Establishing a database of key parameters (such as slip pressure, holding time, moisture content, etc.) standardizes process windows, reducing debugging time and scrap rates. Mold design improvements are equally critical. High-precision polishing or applying lubricant coatings to mold inner walls effectively reduces friction resistance of powder or slurry, significantly enhancing filling efficiency. Simultaneously, scientifically adding venting channels prevents defects like bubbles and chipped corners caused by gas entrapment, with particularly notable effects on complex, irregularly shaped components.

III. Innovations in Drying and Sintering Technologies

The drying stage represents both a production bottleneck and a high-defect zone. Traditional hot-air drying relies on capillary action, often causing uneven shrinkage and cracking in green bodies. Innovative adoption of radiation drying or liquid drying technologies enables heat transfer from the interior outward, improving drying uniformity by 40%. This accelerates drying speed while virtually eliminating cracking risks. Refining sintering regimes is key to enhancing product performance. Optimizing heating rates, holding times, and kiln atmospheres accelerates densification, yielding microstructures with uniform grain sizes. For instance, introducing controlled vapor atmospheres during specific stages effectively promotes material migration, boosting density while improving light transmittance and surface flatness.

IV. Scientific Regulation of Materials and Formulations

The inherent properties of raw materials determine the upper limit of forming capabilities. Selecting high-purity powders with narrow particle size distributions and implementing precise formulation ratios form the foundation for enhancing green body strength and sintering activity. During slurry preparation, adding high-efficiency dispersants optimizes slurry viscosity and stability, reduces particle agglomeration, and ensures consistent forming quality. Improvements to auxiliary materials like glazes and binders are equally crucial. Introducing high-performance binders into glaze slurries effectively reduces powdering rates on glazed surfaces, thereby decreasing equipment downtime and ensuring smooth production line flow.

Conclusion

Enhancing ceramic forming efficiency and production capacity requires integrating automated equipment, implementing intelligent parameter control, and upgrading drying and sintering technologies. This holistic approach builds core competitive advantages in the fiercely competitive market, ultimately achieving the dual goals of high quality and high efficiency.