With the trend toward integrated bathroom design, large-sized countertop basins have become key elements in enhancing both aesthetics and functionality. However, increased dimensions pose significant challenges to ceramic slip-casting processes: the green body is more prone to cracking due to uneven shrinkage during drying, and the risk of deformation during demolding sharply rises due to increased weight and surface area. This also places extremely high demands on mold structural strength, kiln load-bearing capacity, and temperature uniformity.

The challenges in forming large-sized basins primarily manifest in material selection, process control, and structural stability. Below are common challenges and corresponding solutions:

1. Material Selection and Performance Balancing

Challenge: Large basins demand high material strength, durability, and visual appeal. For instance, ceramic basins may crack due to excessive size, while engineered stone basins require a balance of hardness and toughness.

Solution: Prioritize high-strength, low-shrinkage materials like premium ceramics or composite engineered stone. For ceramic sinks, adopt segmented molding followed by assembly to reduce overall forming pressure; engineered stone sinks require optimized formulations with fiber reinforcement to enhance impact resistance.

2. Forming Process Complexity

Challenge: Forming large-sized basins is technically demanding, with traditional slip casting or compression molding often failing to ensure uniformity and precision. For instance, slip casting may result in uneven body density, causing deformation after firing.

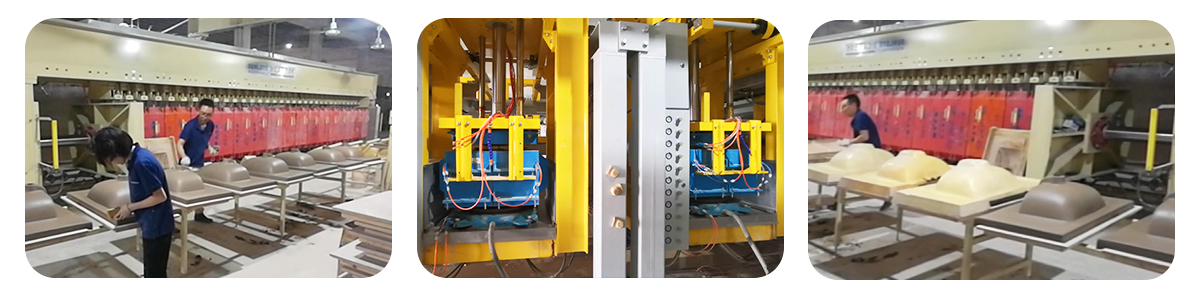

Countermeasures: Employ advanced forming techniques like high-pressure slip casting to achieve uniform density and minimize internal defects. Implement staged sintering during firing based on material properties to prevent localized shrinkage.

3. Structural Stability and Support Design

Challenge: Large basins carry significant self-weight, demanding robust support structures. Improper support design may cause sagging or cracking.

Countermeasures: Reinforce the basin's base support structure, such as adding support legs or brackets. Alternatively, adopt a modular design by dividing the basin into sections for separate installation and assembly, reducing overall installation complexity.

4. Surface Treatment and Aesthetics

Challenge: Surface treatment of large-sized basins is difficult, prone to imperfections or color variations. For example, grinding and polishing processes may yield uneven results due to excessive size.

Countermeasures: Employ automated surface finishing equipment to ensure uniform grinding and polishing. For ceramic basins, increase glaze thickness to enhance surface smoothness, stain resistance, gloss, and abrasion resistance.

These strategies effectively address challenges in forming large-sized basins, ensuring product quality and performance. As a premium element in bathroom design, large-sized basins represent not only an aesthetic breakthrough but also a comprehensive test of craftsmanship and materials. With the continuous advancement of high-pressure slip casting, composite materials, and intelligent processing technologies, the molding challenges posed by size are gradually being overcome. In the future, large-sized basins will undergo continuous optimization in material properties, structural design, and surface processes, achieving dual enhancements in functionality and aesthetics. This will bring more diverse and refined application possibilities to bathroom spaces.